Jaw crusher is mainly used for medium crushing and fine crushing of raw materials. The crushing mode is curved extrusion type. It has the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable operation, simple maintenance and economic operation cost.

Dear [PE Jaw Crusher] customer, it is very lucky that you can find us in the vast information! Hengtong crushing equipment is a PE Jaw Crusher product supply enterprise. Since its establishment, it has been deeply engaged in the Crusher field,to provide high cost performance PE Jaw Crusher products for Crusher customers! The following is the relevant information of PE Jaw Crusher product organized by Hengtong crushing equipment for you.

Description

Jaw crusher is mainly used for medium crushing and fine crushing of raw materials. The crushing mode is curved extrusion type. It has the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable operation, simple maintenance and economic operation cost. It is widely used in mining, smelting, building materials, highway, water conservancy, chemical industry and many other departments to crush all kinds of materials with compressive strength less than 320 MPa.

Product advantages

Jaw crusher has the following performance characteristics:

1. The crushing ratio of jaw crusher is about 15, and the particle size is uniform;

2. It has a large range of adjustment and reliable operation;

3. The jaw crusher has high production efficiency and low energy consumption. Compared with ordinary fine jawbone, the processing capacity of jaw crusher is increased by 20-35% and the energy consumption is reduced by 15-20%;

4. The crushing chamber of the crusher is deep and there is no dead zone, which improves the feeding capacity and output;

5. Under the same process conditions, the service life of jaw plate can be extended by more than 3-4 times, especially for high abrasive materials;

6. The lubrication system is safe and reliable, the parts are easy to replace, and the maintenance workload is small.

Working Principle

The jaw crusher is mainly composed of pull rod, spring, adjusting pad, adjusting seat, elbow plate, moving jaw, eccentric shaft, fixed wedge of moving jaw, moving jaw, side guard plate, fixed jaw plate, frame and other equipment. The crushing mode of PE Series jaw crusher is curved extrusion type. The belt and pulley are driven by motor, and the moving jaw moves up and down through eccentric shaft, When the moving jaw rises, the angle between the elbow plate and the moving jaw becomes larger, which promotes the moving jaw plate to approach the fixed jaw plate. At the same time, the material is crushed by extrusion, rubbing and grinding;

When the moving jaw goes down, the angle between the elbow plate and the moving jaw becomes smaller, and the moving jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring. At this time, the crushed materials are discharged from the lower opening of the crushing cavity. With the continuous rotation of the motor, the crushing mobile jaw makes periodic crushing and discharging to realize mass production.

In the era of intelligent manufacturing, the craftsman spirit is not outdated, and its essence is to do things and wholeheartedly. China Gongyi Hengtong Machinery Factory has been dedicated to for many years, sticking to the Crusher field, and polishing "craftsman" level talents on PE Jaw Crusher!

|

Hengtong takes you to see China! China's long-standing culture has been instrumental in shaping its rise as a populous country.

|

Thank you for your time!

If you are interested in our products and like to have further information, please do not hesitate to contact our offices or our international distributors

Huangshan Road,Gongyi City,Henan China

Phone: +86 18236970567

Email: kumachine@163.com

Whatsapp: {whatsapp}

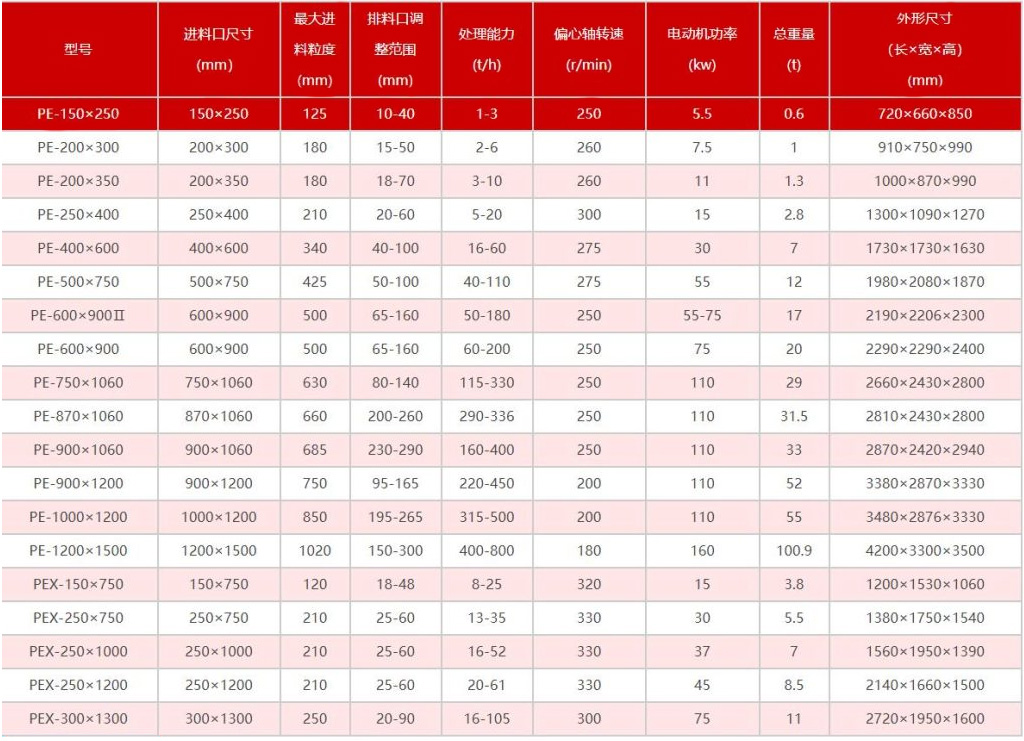

Technical Data